The dimensions of a closed rectangular box are measured as its length, width, and height. These dimensions are crucial for determining the volume and functionality of the box. Understanding how to accurately measure and apply these dimensions is essential in various fields, including engineering, packaging, and logistics.

This guide delves into the concept of dimensions in rectangular boxes, explores measurement techniques, and discusses their practical applications. It also highlights the impact of dimension variations and provides design considerations for optimizing closed rectangular boxes.

Dimensions of a Closed Rectangular Box: The Dimensions Of A Closed Rectangular Box Are Measured As

A closed rectangular box is a three-dimensional shape with six faces, each of which is a rectangle. The length, width, and height are the dimensions that describe the size of a rectangular box. The length is the distance from one end of the box to the other, the width is the distance from one side to the other, and the height is the distance from the bottom to the top of the box.

The volume of a rectangular box is the amount of space it occupies. The volume is calculated by multiplying the length, width, and height of the box. The formula for the volume of a rectangular box is V = lwh, where V is the volume, l is the length, w is the width, and h is the height.

Closed rectangular boxes are used in a variety of applications, including packaging, shipping, and storage. They are also used in engineering and construction to create structures and components.

Measuring the Dimensions

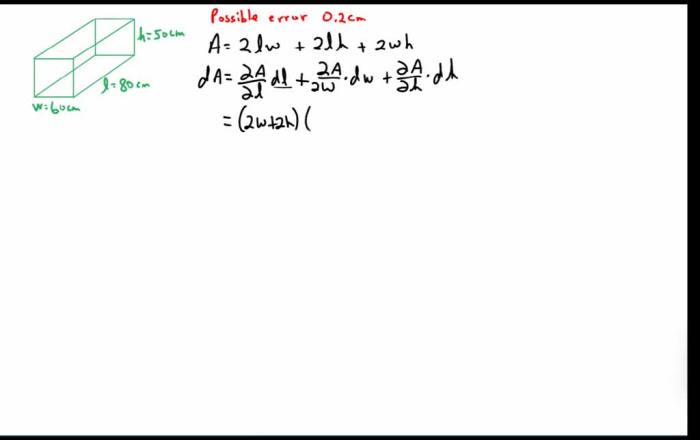

The dimensions of a closed rectangular box can be measured using a variety of tools, including a ruler, tape measure, or calipers. It is important to measure the dimensions accurately and precisely, as even small errors can lead to significant errors in the calculated volume.

There are a few potential sources of error when measuring the dimensions of a closed rectangular box. These include:

- The accuracy of the measuring tool

- The precision of the measurement

- The condition of the box

- The skill of the person making the measurement

Applications of Dimension Measurements

The dimensions of a closed rectangular box are used in a variety of applications, including:

- Packaging: The dimensions of a box are used to determine the size of the packaging material needed to ship the product.

- Shipping: The dimensions of a box are used to calculate the shipping costs.

- Storage: The dimensions of a box are used to determine the amount of space required to store the product.

- Engineering: The dimensions of a box are used to design and build structures and components.

- Construction: The dimensions of a box are used to calculate the amount of material needed to build a structure.

Impact of Dimension Variations

Variations in the dimensions of a closed rectangular box can have a significant impact on the volume, shape, and functionality of the box. For example, a box that is too small may not be able to hold the product, while a box that is too large may be more expensive to ship.

It is important to control the dimensions of a closed rectangular box within certain tolerance limits. This ensures that the box meets the required specifications and performs as intended.

Design Considerations for Closed Rectangular Boxes

When designing a closed rectangular box, there are a number of factors to consider, including:

- The material properties of the box

- The load capacity of the box

- The environmental conditions that the box will be exposed to

- The cost of the box

By considering these factors, engineers can design closed rectangular boxes that meet the required specifications and perform as intended.

Query Resolution

What is the formula for calculating the volume of a closed rectangular box?

Volume = Length × Width × Height

What are the potential sources of error in measuring the dimensions of a closed rectangular box?

Inaccurate measuring tools, human error, environmental factors (e.g., temperature variations)

Why is it important to consider tolerance limits in designing closed rectangular boxes?

Tolerance limits ensure that the box meets specific requirements and functions as intended, despite variations in manufacturing.